Mechanic Pallet Changer Station

Metallic pallet changer station devices are designed to help companies that handle palletized products to replace a damaged pallet from under a stack of packages. These mechanic devices are sturdy, easy to use and offer optimal protection to the goods while the pallet is changed.

-

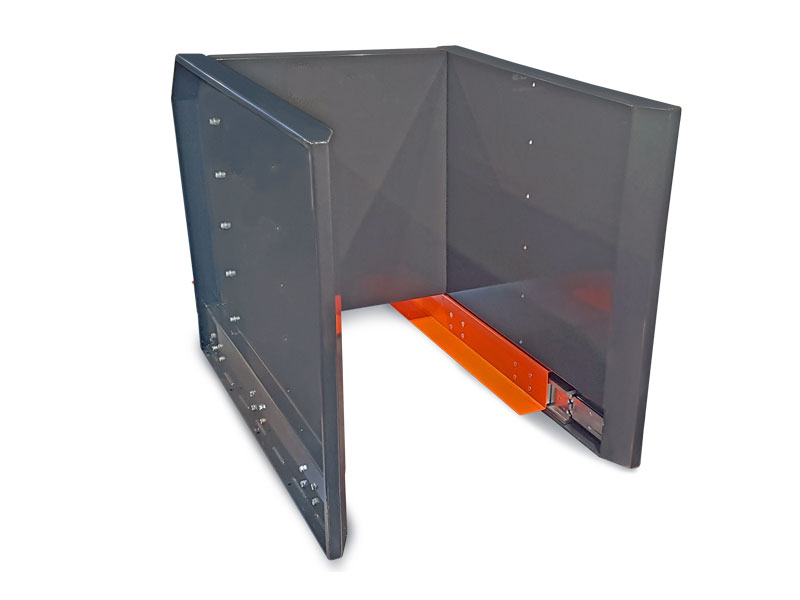

Pallet Changer

The pallet changer is an innovative logistic device for busy warehouses and distribution hubs. It takes only one person to use the pallet changer and replace a damaged pallet from under a stack of products. Within just a few seconds, the stack of products sits safely on a new pallet and is ready for shipping.

How Does the Pallet Changer Work?

This pallet changing device has 3 metallic sides. The operator approaches its open side with a forklift with the stack of products on the damaged pallet, and the new pallet on top of the stack. After placing the stack of product inside the pallet changer, the forklift lowers the new pallet and pushes it under the stack.

The 3 vertical sides hold the stack of products tightly. As the new pallet is pushed in, the old one is pushed out. The stack of products now sits on the new pallet, and the operator can retrieve them with the forklift. That’s all!

Why Should Your Business Choose the Pallet Changer?

Among other logistic equipment, pallet changing devices are a must-have in any warehouse. Pallets can get damaged by exceeding the maximum load or rough handling. If the products are shipped on a damaged pallet, they can be deteriorated beyond repair or become unfitted for selling.

With pallet changer, you get:

- a strong and reliable device made of 4 mm steel sheet

- compact sizes, ideal for tight places in busy warehouses

- easy to use, training takes only a few easy steps

- recommended for EURO, INDUSTRY and custom sized pallets

This model of pallet changer is also available in stainless steel for clean-rooms and food production facilities. It is available in four standard colors:

- RAL 5012 light blue

- RAL 6000 patina green

- RAL 7016 anthracite gray

- RAL 7035 light gray.

Other colors available upon request.

Examples of use:

- transferring products from wooden pallets to plastic cleanroom/hygienic pallets before entering sterile spaces, or the other way round;

- moving goods from leased pallets (Chep, La Palette Rouge) on EPAL pallets or the other way round;

- replacing defective or damaged pallets during transport;

- changing pallets used during transport with ESD pallets for ESD cleanrooms or the other way round;

- US FED STD 209E cleanroom standard;

- BS 5295 cleanroom standard;

- ISO 14644-1 cleanroom standard.

-

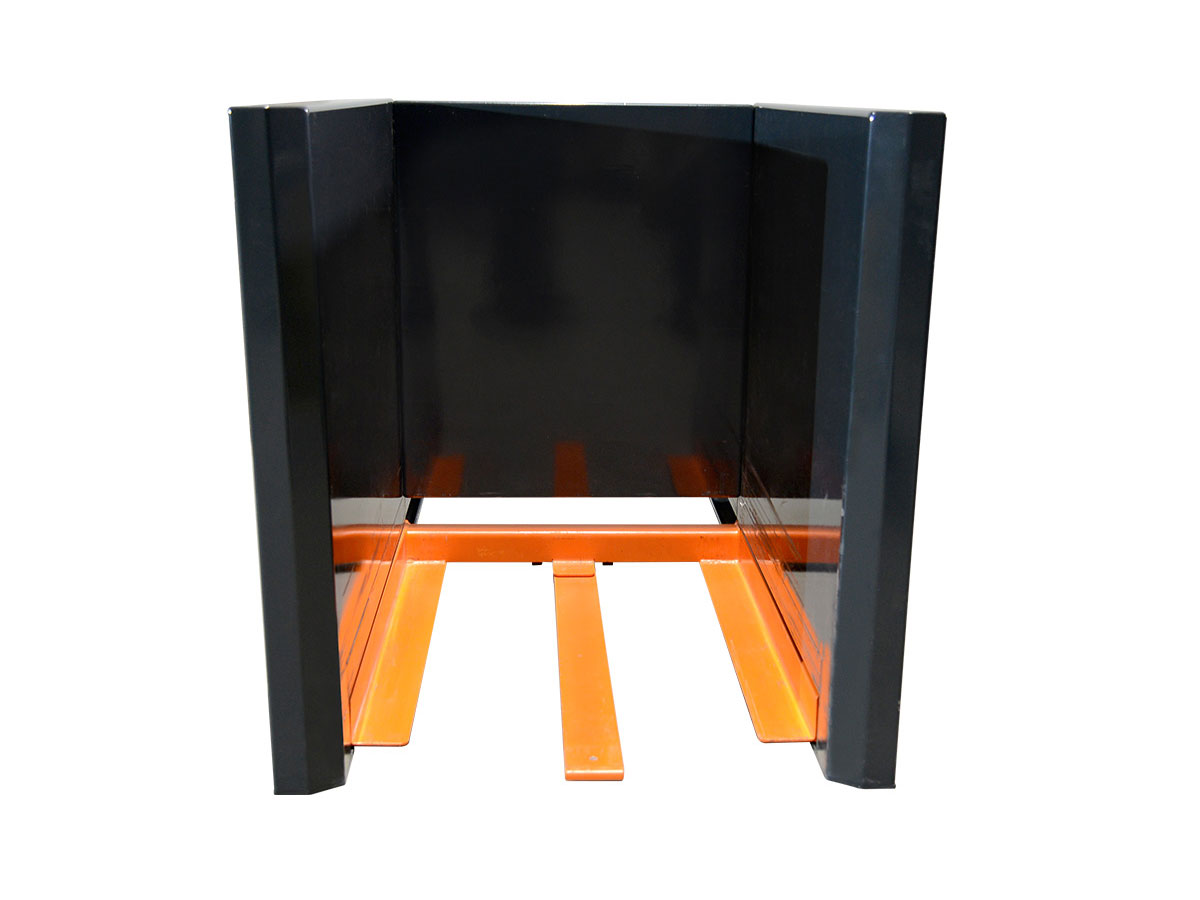

Ultra Pallet Changer

The ULTRA pallet changer helps the warehouses and distribution companies to safely and easily replace damaged pallets from under stacked products. This device has a modular design that adapts for two types of pallets: EURO and ISO. It can also be used to replace a wooden pallet with a plastic pallet.

How Is ULTRA Pallet Changer Used?

The design of this innovative pallet changer is simple and efficient. Three sturdy walls will hold the stack of products in place. The three tines at the bottom facilitate the pallet to slide out and back in. They can also be adapted in widths to fit the size of the pallets.

The operator uses a forklift to place the stack within the ULTRA pallet changer, and then returns with the new pallet. As the operator slides the new pallet under the stack, the old one slides out. When the operator removes the stack of products, the old pallet slides back within the pallet changer.

Benefits of ULTRA Pallet Changer

This type of pallet changer is a versatile warehouse device that helps your employees replace a damaged pallets in less than a minute. It can be adapted for the most popular models of pallets on the market, and has several useful features, such as:

- sliding tines with automatic return

- extra third support for heavy loads

- packing plates made of 5 mm sheet steel to compensate for pallet height differences

You can also order the ULTRA pallet changer to fit the specific size of the pallets used in your company, such as: half pallets, one-way pallets, GMA pallets (USA models). Other further customization options include:

- stainless steel body for superior hygiene

- higher load-bearing capacities

- special colors

Examples of use:

- transferring products from wooden pallets to plastic cleanroom/hygienic pallets before entering sterile spaces, or the other way round;

- moving goods from leased pallets (Chep, La Palette Rouge) on EPAL pallets or the other way round;

- replacing defective or damaged pallets during transport;

- changing pallets used during transport with ESD pallets for ESD cleanrooms or the other way round;

- US FED STD 209E cleanroom standard;

- BS 5295 cleanroom standard;

- ISO 14644-1 cleanroom standard.

-

Octabin Pallet Changer

Octabin containers are increasingly popular for shipping bulky goods, and for this reason we offer you the innovative octabin pallet changer. This device has a perfect shape to support octabins while the damaged pallet on which they are placed, is changed.

The Octabin Pallet Changer: Simple Operation and Maximum Efficiency

This special pallet changer has five side walls designed to fit an octabin perfectly. The operator places the stacked octabins inside the pallet changer with a forklift. By sliding the new pallet under the stack, the old, damaged pallet is pushed out.

Now the operator can retrieve the stack of octabins sitting on the new pallet. This is it!

Key Features of the Octabin Pallet Changer

The special model of pallet changer for octagonal bulk boxes is available for standard square pallets 1140 x 1140 mm. It can withstand loads of up to 1000 kg.

Examples of use:

- transferring products from wooden pallets to plastic cleanroom/hygienic pallets before entering sterile spaces, or the other way round;

- moving goods from leased pallets (Chep, La Palette Rouge) on EPAL pallets or the other way round;

- replacing defective or damaged pallets during transport;

- changing pallets used during transport with ESD pallets for ESD cleanrooms or the other way round;

- US FED STD 209E cleanroom standard;

- BS 5295 cleanroom standard;

- ISO 14644-1 cleanroom standard.

-

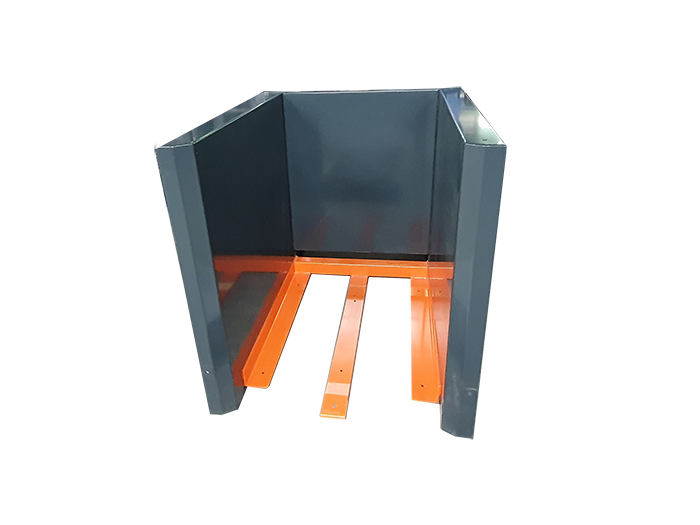

Pallet Stacking Device

The order and an efficient use of space are of maximum importance in any warehouse, and the pallet stacking device helps your company in this regard. The simple and ingenious design of this device, helps your workers to neatly stack empty pallets and retrieve them with the forklift when they are needed.

How Does the Pallet Stacking Device Work?

This device is custom made according to your needs. It consists of three U-shaped walls, with an opening at the bottom of the horizontal wall to slide pallets in and out. We can manufacture this device to stack various numbers of pallets, and to fit various pallet footprints: EURO, ISO, custom, etc.

The operator uses a forklift to perform various actions:

- add empty pallets to the stack

- remove a full stack to place it in storage areas

- retrieve pallets for order picking as necessary

This is the simplest and most efficient way of keeping your warehouse floor clutter free. At the same time, it prevents the accidental damage of empty pallets forgotten on floors or shelves. The pallet stacking device is made of sturdy and reliable materials, and designed to protect the pallets while they are slide in and out of it.

What Other Customization Options Can You Choose for the Pallet Stacker?

As we explained above, the pallet stacking device is produced according to your specifications for height and widths. The standard models are available in the following colors:

- RAL 5012 light blue

- RAL 6000 patina green

- RAL 7016 anthracite grey

- RAL 7035 light grey

Other colors are available upon request.

-

Why Should You Business Use Mechanic Pallet Changer Station Devices?

Motorized pallet changers are quite difficult to use. They require special training and there is always the risk of accidents due to improper operation. They are also expensive, and take up a lot of space in your warehouse.

By comparison, the devices in the mechanic pallet changer station category are very easy to use. Your employees need only minimal training, and they can use the forklifts that you already have on premises.

The compact size of the pallet changing devices makes them an ideal choice for busy warehouses and loading bays, where space is at a premium.

Versatile Equipment for All Types of Pallets

The mechanic pallet changer station can be used for the most popular models of pallets: EURO, ISO and GMA (US models). At the same time, we also have a special pallet changer for octabins. It has a special shape to hold the octagonal bin steadily while the operator changes the pallet underneath.

We encourage you to learn more about each product in the mechanic pallet changer station category, and contact us to discuss your specific application!