Textile separators

Optimal Protection with Textile Separators

Textile separators, whether woven or non-woven, offer ergonomic packaging solutions, primarily serving the automotive industry. Each set of internal textile separators is tailor-designed to meet the specific needs of individual logistic projects.

Adaptable for use with plastic boxes, folding pallet boxes, or custom-built metal racks, these separators ensure that parts remain isolated from each other, averting contact and absorbing vibrations during transit.

Textile compartments afford heightened protection, particularly for oversized or irregular-shaped parts that may not conveniently fit into rigid, regularly shaped compartments.

For parts with irregular shapes, nesting within a larger container is possible, thereby notably enhancing space efficiency.

These separators shield a wide range of component sizes and types, including but not limited to small to long or bulky parts such as headlights, leather-wrapped steering wheels, doors, mirrors, windshields, safety glass components, front/rear bars, handles, dashboard components, appearance parts, and small metal parts, providing top-tier protection against scratches and damage to painted items.

Utilizing high-quality, highly durable materials in the production of separators ensures longevity, and they can be subjected to specialized treatments as needed, such as water resistance, fireproofing, anti-scratch, antibacterial, or antistatic/dissipative (ESD) applications.

-

Textile Pallet Dividers: Horizontal Access

Transportation of long or flat parts is optimally achieved with logistic packaging that features horizontal access. This arrangement facilitates horizontal nesting and provides robust protection against mechanical shocks during transport, handling, and production — offering an excellent ergonomic solution for a diverse range of parts.

We have developed dividers compatible with various packaging solutions, including:

- Flatpac with an open front (yet still foldable) – suitable for containers KTP 114888, KTP 114777, 114999, and Ecopacks. These systems are foldable.

- Magnum Optimum with a collar for storing the textile separator when folded

- A foldable metal rack that collapses along with the separator

- Rigid metal rack

- Trolleys featuring sliding components

These separators can be enhanced with vertical or horizontal reinforcements, plastic plate reinforcements, or technical foam. For items with especially sensitive areas, respective partition regions can be tailored with cuts or outfitted with thermoformed plates to ensure ultimate safety.

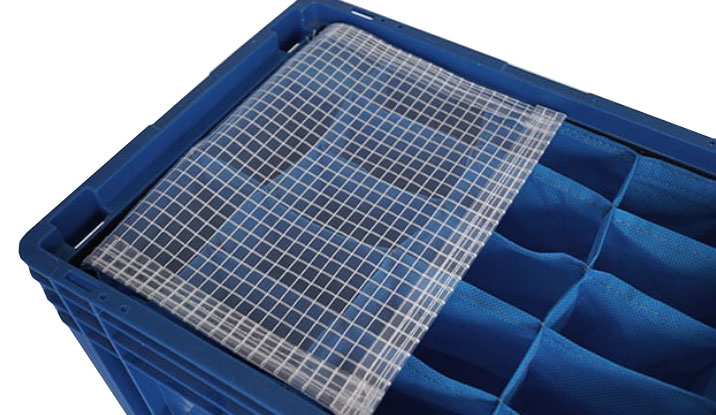

The packaging can be fitted with anti-dust tarpaulins, ensuring clear visibility while maintaining cleanliness.

In-container separators can be effortlessly removed and replaced as they wear or when the container necessitates repurposing for an alternate use.

Heavy metal racks can be maneuvered using tow trucks, providing a comprehensive solution.

-

Textile Pallet Dividers: Vertical Access

Vertical access textile dividers are designed with multi-story functionality. When emptied, upper levels can slide aside, providing access to those below, while also allowing the nesting of pieces.

The sliding systems are adaptable, changing based on content weight. They might utilize bars and eyelets or hooks, and for heavier weights, each employs metal support profiles.

It’s the small design elements that significantly increase ergonomics. Features like the smooth, silent sliding of pouches and the ability to fold empty containers with textile dividers inside create a work environment that’s both efficient and pleasurable.

Textile pockets can be additionally padded with foam for heightened protection. Numerous design innovations ensure that contents within the textile dividers don’t touch each other or any hard container component, providing an extra layer of security.

These systems can be implemented in various packaging systems like Flatpac plastic pallets (KTP 114888, KTP 114777, KTP System 2000, Ecopacks), injected folding pallets (Magnum Optimum, Klappa), metal SLI containers, and assorted metal racks.

-

Textile Box Dividers: Custom, Ergonomic, & Secure

Tailor-made textile separators for boxes are made to accommodate various containers (such as box, box pallet, metal rack) while adhering to specific product features and constraints, as well as the ergonomic demands of the product’s logistic chain.

Predominantly utilized in the automotive industry, these separators also find applications in electronics and the production of delicate precision objects like glass or fragile components for medical devices.

Advantages of Textile Separators:

- Facilitate Folding: Allows boxes to be folded when empty.

- Enable Nesting: Permits the nesting of parts inside the box.

- Ergonomic Use: Ensures ease of use by operators.

The fabrication of these woven materials employs CNC Laser cutting, which simultaneously seals the edges to inhibit thread unraveling. Both manual and automatic machine sewing are deployed in their construction.

-

Choosing the Right Textile and Foam Materials for Protective Dividers

Selecting the appropriate material and design for protective dividers involves a nuanced understanding of the specific needs of the items being stored or transported. Material choices influence protective capacity, cost, and operational efficiency, underscoring the importance of a meticulously tailored approach to packaging design.

Textile options you can choose from:

- Evolon & Tyvek (1082D and 2473L): Recommended for scratch-sensitive surfaces.

- Vapour Fabric: Allows humidity escape while providing rain protection.

- PVC: Offers robust protection and is suitable for various applications.

- TNT Spunbond (PPNT) & Microfiber: Often used for their softness and protectiveness.

- Astonica: A specific-use material based on application needs.

- Royal Fabric, Kevlar, and Felt: Provide enhanced protective properties.

- ESD Fabric: To prevent electrostatic discharge damage.

- Mesh, Pellucid, and Tarpaulin: Pellucid allows visibility, while Tarpaulin offers waterproof properties.

Foam options you can choose from:

- IXPE, LXPE, and EPE: General-purpose foams suitable for various applications.

- Antistatic EPE and Antistatic PU Foam: Prevent static charge buildup.

- ESD Foam: Specifically designed to dissipate electrostatic charges.

- Eva Foam: Noted for its softness and flexibility.

- Laminated Foam: Enhanced strength and protective properties.

Strategic Use of Materials:

- Vapour Fabric is pivotal for situations where moisture control is critical, ensuring internal dryness without trapping condensation.

- Pellucid is vital for applications where visual inspection without package opening is advantageous.

Ergonomic Considerations: To determine ideal ergonomic positioning within containers, aspects like thickness, length, sensitive surfaces, and movement requirements shaping horizontal or vertical placement must be factored in.

Structured Protection:

- Textile materials can be padded on alveolar plastic to construct a rigid anti-scratch divider, ensuring stability and protective efficacy against shocks.

- Adapted interiors assure non-collision and non-friction environments, preventing damage during storage or transit.

Handling & Usage Efficiency:

- Non-woven fabric internal dunnage facilitates easy checking of large parts (e.g., automotive components) by enabling top or lateral opening of the separators.

- Superior foldability of fabrics ensures space and cost efficiency during non-use periods.

- Utilizing non-woven textile packaging, tarpaulin, PVC, and polyamide, notably in the automotive industry, can amplify transportation cost-efficiency by escalating the quantity of transported products by up to 30%.

Streamlining Operations:

- Integrating non-woven Spunbond separators that fold in tandem with outer packaging eradicates the necessity for removal, enhancing operational efficacy on return trips.

Selecting the appropriate material and design for protective dividers involves a nuanced understanding of the specific needs of the items being stored or transported. Material choices influence protective capacity, cost, and operational efficiency, underscoring the importance of a meticulously tailored approach to packaging design.