Big Bags

Specifically crafted for industrial purposes, warehouses, and handling various heavy loads, the Big Bag stands out with its thin, flexible walls, ensuring efficient logistics.

Made from durable Polypropylene fabric, it can be tailored in cubic or cylindrical designs.

Its unique design allows for top filling and bottom emptying, providing an ergonomic solution for warehouse operators.

-

Vacuum Bags

Vacuum packaging redefines the way we store and transport food, preserving freshness and flavor without added preservatives. These bags optimize the internal atmosphere using natural gases, like CO2, which safeguards against insects and microorganisms. Or, for foods sensitive to oxidation, oxygen vacuuming can replace the inner atmosphere to maintain freshness, making it an essential tool for meat, vegetables, and fruit storage.

-

UN Big Bags

UN Big Bags are the only safe way to transport dangerous materials that might affect people’s health and the environment. Hazardous goods can only be transported using packaging that meets all UN regulations.

UN Big Bags to meet all requests come with an assigned code, e.g., 13H3/Z/10.16/A/PA-03/LOGIMARKT 418442/1900/1015.

The UN code contains the following:

- The first 4 characters after UN staple testify to the type of construction of the bag (eg. 13H1 are big bags with no liner and uncoated fabric, 13H2 have coated fabric with no liner, 13H3 uncoated fabric with liner and 13H4 – coated fabric with liner);

- Next letter will indicate the packaging group (Y is designated for packaging groups II and III, while X is designated only for group III);

- The 4 digits separated by a full stop represent the production year and month;

- “A” is the country code;

- The following 4 characters, separated by a hyphen, are the certifying body;

- The code of the producer and the specific FIBC;

- The next 4 digits batch attest the stacking weight test (in kg);

- The last 4 digits stand for the maximum gross weight of the safe working.

UN Big Bags are tested 6 different ways tests before going into production:

- Top lift test

- Stacking test

- Drop test

- Topple test

- Righting test

- Tear test

-

More about Big Bags

Tailored to protect goods from potential risks like impact or temperature fluctuations, Logimarkt promises safe transport and efficient discharge. Customers have the liberty to design bags tailored for their specific requirements.

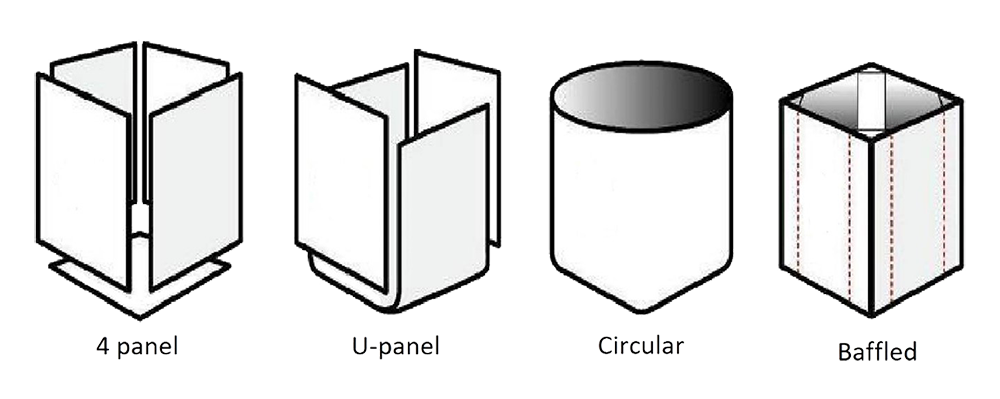

Shapes and Designs

From tubular designs perfect for powders to the U-panel design offering enhanced stability, we offer Big Bags in multiple shapes to suit various industry needs. Furthermore, customize your Big Bag with options ranging from dustproof seams, color prints, coated fabrics, to PE or laminate liners.

Big bags with different shapes, for various industries Opt for the most suitable top:

- Open

- With a charging tube

- Top flap

- Skirt

Choose from the base options:

- Closed

- With an emptying tube

- Skirt

- Fabrics without any protecting properties against electrostatic discharge (type A)

- Antistatic fabric (type B)

- Fabric woven with conductive threads (type C)

Enhance your product with all or any of the additional features:

- Dustproof seams in a wide range of grades

- Color printing

- Customized labels

- Coated or uncoated fabrics

- PE or laminates liners

-

Applications

Discharge utensil for reusable bulk containers with opening and closing valve Logimarkt Big Bag Discharge Utensil

This is a reliable unloading tool without damaging the bag. It is designed to ensure safe and accurate emptying. Further, it allows for bag reuse, eliminating needless replacement costs. It’s ideal for reusable and returnable bags, guaranteeing no damage during discharge.

With this Discharge Utensil, simply open the primary knot of your Big Bag, adjust the tension ring, then position the tool beneath the secondary knot. Secure the tension ring to the discharge hose, then proceed to release the second knot and system slide to discharge contents.

Big bag containers reusable discharge through perforation tool, with valve that can be opened and closed Logimarkt Discharge Utensil via Perforation

Place the plastic accessory beneath the Big Bag’s center, allowing it to penetrate. With the bag positioned atop, elevate it until the emptying system engages. This system, when pulled downwards, simplifies valve operations. To discharge without causing damage, invert the bag, untie one knot, then attach a tension band. Once the Discharge Utensil is beneath the bag’s opening, draw the tension band downwards, affixing it to the accessory. Finally, release the secondary knot and valve to empty.

-

Standard dimensions for big bags

Base dimensions in cm Height of big bag in cm Big Bag volume in m³ 88x88 / 96x76 70 0,6 88x88 / 96x76 80 0,7 88x88 / 96x76 90 0,8 88x88 / 96x76 100 0,9 88x88 / 96x76 110 1 88x88 / 96x76 120 1,1 88x88 / 96x76 130 1,2 88x88 / 96x76 140 1,3 88x88 / 96x76 150 1,4 88x88 / 96x76 160 1,5 88x88 / 96x76 170 1,6 88x88 / 96x76 180 1,7 88x88 / 96x76 190 1,8 88x88 / 96x76 200 1,9 88x88 / 96x76 210 2 88x88 / 96x76 220 2,1 88x88 / 96x76 230 2,2 88x88 / 96x76 240 2,3 Base dimensions in cm Height of big bag in cm Big Bag volume in m³ 107x76 / 88x96 / 92x92 64 0,6 107x76 / 88x96 / 92x92 73 0,7 107x76 / 88x96 / 92x92 82 0,8 107x76 / 88x96 / 92x92 91 0,9 107x76 / 88x96 / 92x92 100 1 107x76 / 88x96 / 92x92 109 1,1 107x76 / 88x96 / 92x92 118 1,2 107x76 / 88x96 / 92x92 127 1,3 107x76 / 88x96 / 92x92 136 1,4 107x76 / 88x96 / 92x92 145 1,5 107x76 / 88x96 / 92x92 154 1,6 107x76 / 88x96 / 92x92 163 1,7 107x76 / 88x96 / 92x92 172 1,8 107x76 / 88x96 / 92x92 181 1,9 107x76 / 88x96 / 92x92 190 2 107x76 / 88x96 / 92x92 199 2,1 107x76 / 88x96 / 92x92 208 2,2 107x76 / 88x96 / 92x92 217 2,3 Base dimensions in cm Height of big bag in cm Big Bag volume in m³ 76x76 95 0,6 76x76 110 0,7 76x76 125 0,8 76x76 140 0,9 76x76 155 1,0 Base dimensions in cm Height of big bag in cm Big Bag volume in m³ 96x96 / 107x88 58 0,6 96x96 / 107x88 66 0,7 96x96 / 107x88 74 0,8 96x96 / 107x88 82 0,9 96x96 / 107x88 90 1 96x96 / 107x88 98 1,1 96x96 / 107x88 106 1,2 96x96 / 107x88 114 1,3 96x96 / 107x88 122 1,4 96x96 / 107x88 130 1,5 96x96 / 107x88 138 1,6 96x96 / 107x88 146 1,7 96x96 / 107x88 154 1,8 96x96 / 107x88 162 1,9 96x96 / 107x88 170 2 96x96 / 107x88 178 2,1 96x96 / 107x88 186 2,2 96x96 / 107x88 194 2,3