Testing Our Packaging

At Logimarkt, we are dedicated to upholding the reliability of our packaging solutions through a meticulous testing regimen. Our team of skilled test engineers and experts remains at the forefront of the latest advancements in packaging tests. They ensure that the solutions we provide to clients are consistently ahead of industry standards.

Testing is not just a process for us. It is a fundamental component of confidence in the packaging we produce. The more confidence we build through our rigorous testing, the fewer worries you’ll have.

Our complete test routines cover a wide range of required assessments. These include impact tests, vibration tests, shock tests, high-pressure tests, drop tests, tilt table tests and enclosed atmospheric tests. Each of these tests is carefully designed to replicate the various challenges your packaging may encounter during its journey.

Our testing protocols cover various aspects in meticulous detail. They ensure durability, resistance to external factors and adaptability to different handling scenarios. Trust Logimarkt to deliver packaging solutions that stand the test of real-world challenges, giving you peace of mind with every shipment.

We go beyond standard practices by conducting thorough testing. Our objective is to minimize or eliminate any potential damage that could occur during the life cycle of the packaging.

Our dedicated testing facility is a service in its own right. It receives all types of packaging materials including plastic, cardboard and metal. Delving into the complexities of a product’s journey from warehouse to store or end-user, we design a meticulous testing circuit that addresses all possible risks along the way. Our ultimate goal is zero damage to stored or shipped products.

Our tests are based on state-of-the-art machines that receive precise calibration to simulate real-life situations. This ensures accurate and reliable testing. Each test is documented in detail and the results are followed by suggestions for improvement. For this we draw on our extensive experience in a wide range of protective packaging solutions.

With Logimarkt, you can trust that your goods are in safe hands. We constantly strive for excellence in preventing damage and improving the overall reliability of your packaging solutions.

Shock/ Impact Testing

In the unpredictable realm of logistics, containers face the constant threat of drops and bumps during transit or handling. At Logimarkt, we understand the critical need to protect your packaging against these risks.

Containers can collide with other boxes or objects such as forklifts. Our Shock/Impact Testing is designed to simulate these real-life scenarios. We conduct comparative tests involving the use of protective materials such as cushions. The aim is to evaluate the efficiency of impact force absorption. This testing procedure is most effective when accompanied by a vibration test. In this way, a complete analysis of the strength of the packaging is achieved.

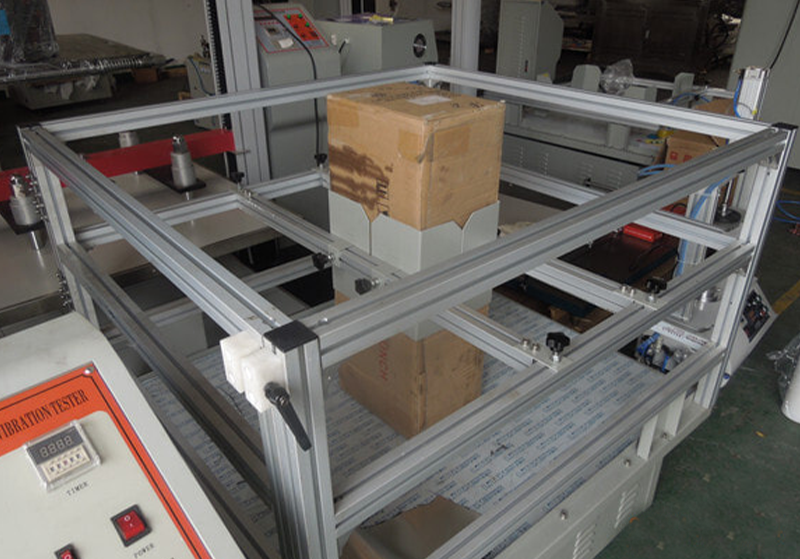

Vibration test

To ensure your packaging can handle the ups and downs of transit, we use vibration tests. These tests involve constant and intermittent vibrations, gradually increasing in intensity until we find the breaking point for each package or product. We then compare this to potential real-world situations.

The vibration test is often paired with our shock test to give a complete picture of the longevity of your packaging. At Logimarkt, we keep it simple – we make sure your products stay safe during the twists and turns of your journey.

Horizontal Shock Testing

Our horizontal shock testing is designed to replicate actual railcar coupling conditions. Truck docking motions and the robust handling linked to forklift operations are simulated as well.

Tailored to match the anticipated stress levels during the handling of specific products, the test intensity is finely adjusted. This ensures your packaging is well-prepared to endure the horizontal shocks it may face during transit and handling. At Logimarkt, our focus is on delivering solutions that stand strong against the practical challenges of the shipment environment.

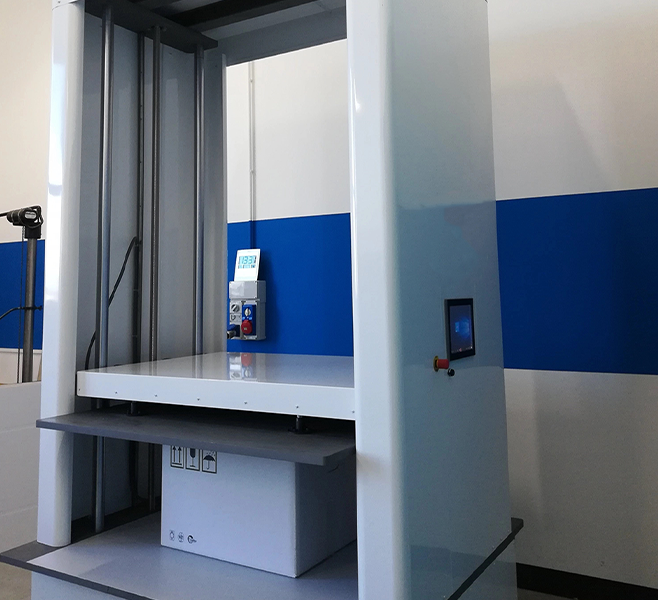

Compression/ Pressure Test for Stackability Assessment

Our compression test is a crucial step in determining the stackability of a given package.

By gradually increasing the compression, we identify the breaking point. This critical measurement determines the stackability of boxes, pallets or other containers. This applies both during static storage and during road transport.

We always ensure that the packaging we produce not only protects the contents but also optimizes space efficiency, providing reliable solutions for both storage and transit scenarios.

Drop test for Box Durability

Specifically designed for boxes, the drop test is a targeted assessment of their resilience.

Boxes get dropped from heights relevant to their intended applications. A series of ten drops are conducted: first on the most fragile corner, followed by drops on each adjacent edge, and finally, one on each face of the box. Post-drops, both aesthetic and functional damages to the box and its contents are meticulously examined. The positioning of items within the box is considered as well. The primary objective of this test is to guarantee impeccable protection for your goods. It ensures that your packaging stands up to real-world impact scenarios.

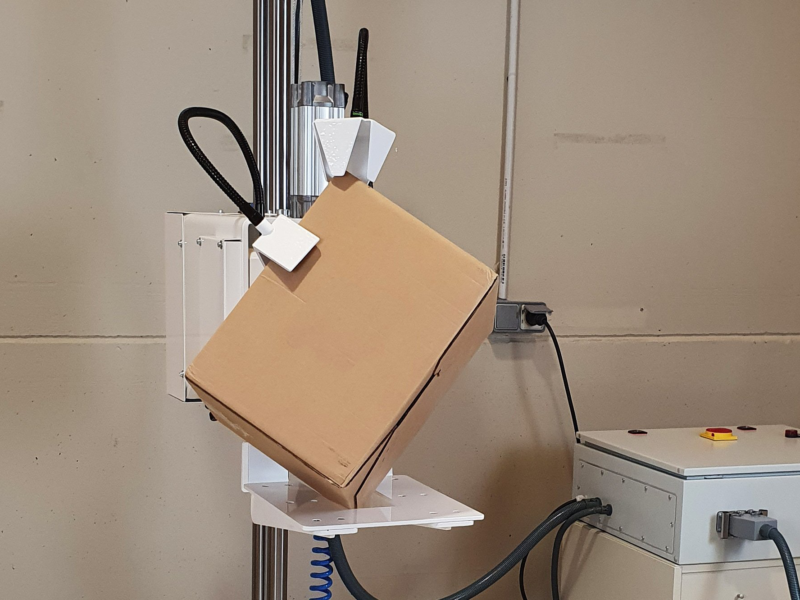

Edge Drop Test

Tailored for substantial boxes or containers, the edge drop test assesses the durability of sizable packaging solutions. In this test, the packaging is deliberately dropped from a specific height onto a concrete floor, replicating potential real-world scenarios. Multiple drops are made and the results are recorded with care.

This focused evaluation ensures that large-scale packaging not only withstands edge impacts but also maintains its structural integrity over repeated drops.

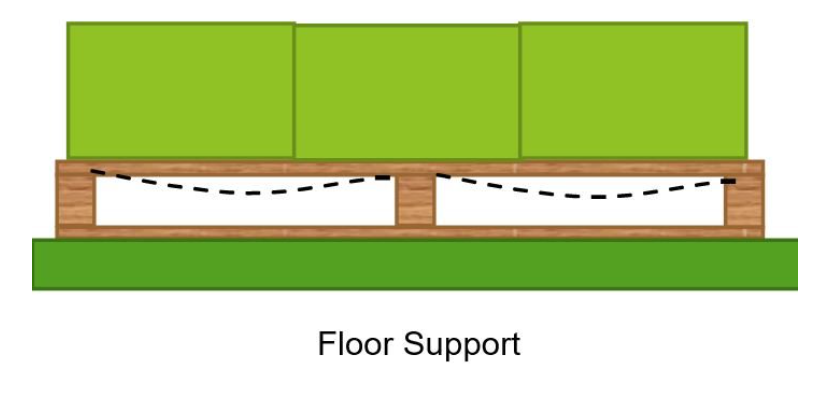

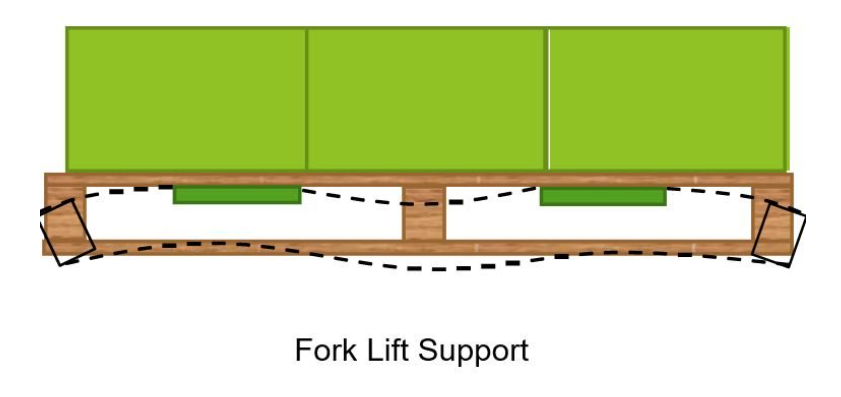

Pallet-in-Rack Test for High-Stored Plastic Pallets

This test is a specialized examination ensuring both product safety and personnel well-being.

The procedure involves placing plastic pallets on a metal rack and loading them with sandbags. Over a 7-day period, the bending of the pallet is meticulously measured. The criterion for success is that the bending must not exceed 20 mm. This test is conducted at various locations on the metallic rack to comprehensively validate the safety and durability of the plastic pallets under different conditions.

Tilt Testing Stacked and Wrapped Products:

Primarily designed for assessing the stability of products stacked on pallets and enveloped in plastic foil, the tilt test is instrumental in ensuring the robustness of packaging.

Conducted by subjecting the load to various angles and stress, this test evaluates the effectiveness of the cling film, wrapping technique, and the number of layers required to withstand transit conditions. The transcript resulting from this test includes recommendations for the type of cling film, the necessary tension, and, if applicable, the optimal settings for the wrapping machine.

Atmosphere Testing

The atmosphere testing procedure aims to analyse the stability of packaging under diverse humidity and temperature conditions.

This test is performed in a test chamber. The controlled environment allows temperature variations between -40 °C and +90 °C. Humidity values are between 5% and 95%. The results obtained from these tests are essential for setting the limits for the packaging solution tested. Logimarkt experts guarantee customers that our packaging can resist a wide range of climatic conditions.

We prioritize thorough testing to ensure the resilience of your packaging, reducing concerns related to the stresses of varying atmospheric conditions.

AEI Test: Advanced Pressure Analysis for Packaging Design

The AEI (Analysis for End Interest) test is a sophisticated software simulation specifically tailored for pressure testing.

Primarily employed for thermoformed trays, this tool plays a crucial role in the design phase. It helps determine the optimal shape and material thickness when creating new items. In addition, for existing packages, the AEI test highlights stress limits. It aids in refining and optimizing designs without the need for extensive prototyping or physical testing.

As a powerful design tool, AEI testing is an effective way to establish critical parameters. This way, your packaging solutions are not only innovative, but also resistant under different pressure conditions. At Logimarkt, we use state-of-the-art technology to increase the efficiency and accuracy of our packaging design processes.